Senergy Unveils New Pingshan Manufacturing Site in Shenzhen with Impressive 10GW Annual Capacity

Shenzhen Senergy Technology Co., Ltd., a leading solar PV inverter and solution provider, has inaugurated its new Pingshan Manufacturing Site in Shenzhen on August 1st 2023. This pivotal step underscores Senergy’s commitment to innovating next-generation intelligent energy products and championing Net-Zero Emission objectives.

Senergy’s new Pingshan Site, spanning 24,000 square meters, serves as a hub for R&D and intelligent manufacturing of on-grid and hybrid PV inverters and solutions. With over 100 R&D experts and 700+ manufacturing staff, it pioneers PV inverter technologies while exploring cutting-edge advancements, components, and processes. The site is equipped with top-tier automated production equipment, elevating Senergy’s annual manufacturing capacity from 3GW to an impressive 10GW upon full-line operation.

Facilities + Talents to Drive Innovation

Senergy attaches great importance to the R&D and application research of new PV technologies and products. This embodies the original purpose of the Pingshan Site and remains the core mission of the company moving forward.

Regarding R&D facilities, the new Site boasts cutting-edge, intelligent R&D laboratories of over 1,000 square meters, fostering the development of on-grid and hybrid PV inverters ranging from 2kW to 500kW. Currently, the R&D laboratories have successfully procured, installed and commissioned an array of advanced equipment, including imported PV simulators, high-power grid simulators, and high-power load equipment. These assets can fulfill diverse research and certification testing requirements, generating test data recognized by several reputable testing organizations. The forthcoming feature at the new Site will enable authorized testing endorsed by certification bodies, thus enhancing the overall testing capabilities.

In the realm of R&D talents, the Pingshan Site is spearheaded by senior domestic power electronics experts, comprising elite members deeply rooted in PV inverter technology, known for their rapid growth capabilities. The majority of the team possesses over 5 years of R&D experience in the power electronics industry, with core management members and technical experts amassing over 15 years of inverter R&D. The team holds numerous core patents, showcasing the ability for independent development and products customization. This robust foundation empowers them to deliver a comprehensive range of efficient, high-quality services to customers.

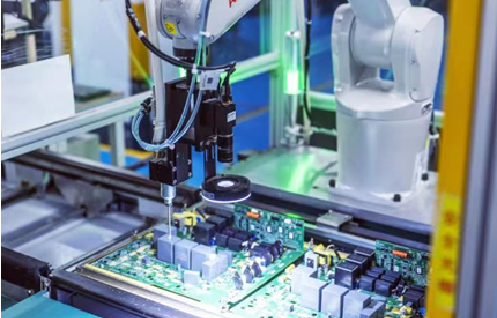

Intelligent Manufacturing to Enhance Quality

Amid demands for cost reduction and efficiency enhancement, alongside the global trend of technology iteration, the PV market has gradually shifted towards high-quality production capacity and the concentration of prominent brands. This aligns perfectly with Senergy’s trajectory.

Senergy’s Pingshan Site boasts 16 cutting-edge automated production lines, coupled with digital management processes and strict testing and quality management systems. This underscores their pioneering stance in intellectual manufacturing, enabling the delivery of high-quality inverter products. For instance, the PCBA production line integrates the most advanced production equipment, process technology, and automation solutions. The line also features AI/SMT and plug-in components, using diverse specialized equipment to achieve full-process MES data traceability, thereby facilitating quality management, smart manufacturing, and competitive products offerings. Notably, the inverter production lines cater to both residential and commercial on-grid solutions, as well as various energy storage products. With fully automated testing cabinets, intelligent aging testing booths equipped with robotic arms, and IP65 waterproof airtight testing facilities, these lines can attain an annual total output of up to 10GW.

Rigorous Quality Management to Guarantee Quality

Senergy’s products are meticulously crafted, strictly adhering to the QC and GP systems across the entirety of the production journey. Leveraging the comprehensive PCBA full-industry processing and production model, Senergy upholds rigorous quality control at every phase. From the 3D solder paste thickness testing, initial optical inspection, post-soldering second optical inspection, to subsequent aging safety regulations and ATE testing, automatic aging, post-aging ATE testing, and air tightness testing – every step acts as a “protective shield” safeguarding product performance. These combined efforts have consistently earned Senergy’s products a well-deserved global reputation and industry recognition.

Senergy’s commitment spans from inverter R&D to manufacturing, fueled by the customer-first, quality-first and technology-driven mindset. The grand opening of Senergy Pingshan Site marks a significant milestone in their journey of innovative and intelligent manufacturing. Embracing this moment, Senergy is poised to play a more profound role in the global energy transition, contributing to the dynamic evolution of the solar PV landscape.

About Shenzhen Senergy Technology Co., Ltd.

Shenzhen Senergy Technology Co., Ltd., the wholly-owned subsidiary of Asian Power Devices Inc. (APD), is a high-tech solar energy company that supports customers through versatile collaboration approaches to advance their next-generation PV inverters. By combining over 35 years of experience in power electronic products management and nearly 20 years of expertise in PV inverter development and manufacturing, Senergy offers a broad portfolio of products suitable for residential, commercial, large-scale ground stations, and various energy storage stations.

For more details, please visit https://us.senergytec.com/.